About Asiamed & TeWa

5th Jul 2022

asiamed was founded in 1989 by physicians with the objective of providing acupuncture professionals with products of superior quality and with all types of needles used in acupuncture.

asiamed and TeWa, their two brands of acupuncture needles, cover the entire range of acupuncture needles in use. You can choose from more than 30 different types with a total of over 300 variants.

asiamed owes the success of quality products to their motivated staff. The international asiamed team consists of skilled employees that operate on our German sites in Suhl (Thuringia) and Munich-Pullach (Bavaria).

ASIAMED STANDS FOR:

- Top-quality products due to controlled and automated production processes

- Quality control in Germany

- Continuous product improvement

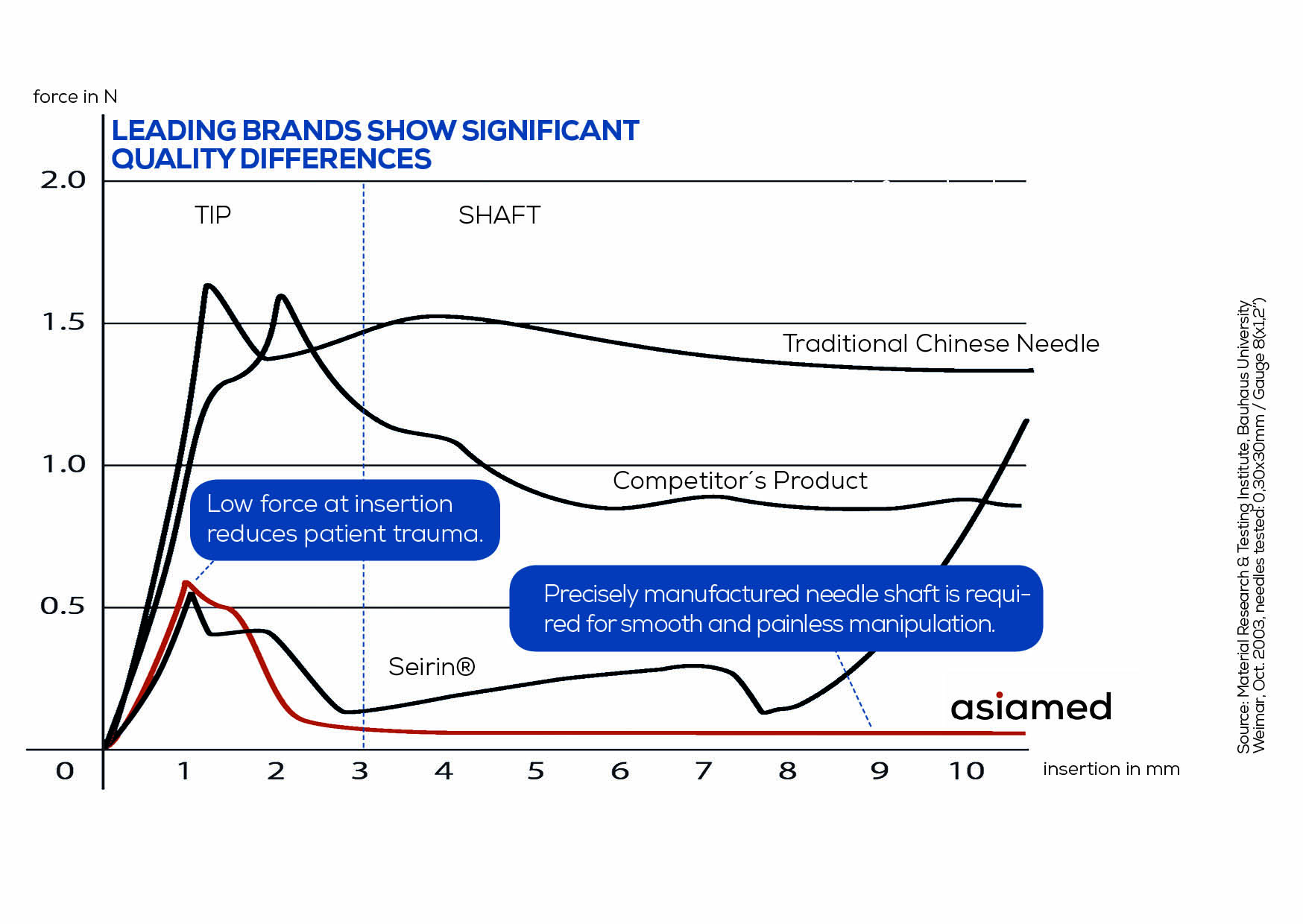

asiamed's top-quality products make a tangible difference in acupuncture treatments. The outstanding quality of asiamed acupuncture needles is manifested in their particularly gentle insertion characteristics. This is one of the reasons for their great popularity and high acceptance.

EXCEPTIONALLY GENTLE INSERTION

Whether a needle causes pain when piercing the skin depends on how easily it can penetrate the upper skin layer (cutis). This is because the cutis has a large number of pain receptors, unlike the subcutaneous skin tissue.

Here is a comparison of the particularly gentle insertion characteristics of asiamed acupuncture needles:

Acupuncturists and patients aim for a successful treatment. In reaching this goal, an exceptionally gentle penetration of the acupuncture needle into the skin plays an important role.

In the production of excellent acupuncture needles, five components are decisive:

- Quality of the applied steel -Low-quality steel contains entrapped air that would cause a break of the material due to the extremely thin wire diameters. asiamed only uses finest quality medical stainless steel to assure the unique flexibility and a flawless material compositon.

- Precision-sharpening of the pinpoint

The grinding and sharpening of a cambered pinpoint to a length of only 0,2 mm is counted, considering the extremely thin diameters of the needles, to the fine arts of automatic production. asiamed has designed and developed high-precision machines for processing steel specifically for the fabrication of acupuncture needles in collaboration with universities and manufacturers. - Accurate smoothing of the surface

The polishing and grading of the needle requires experience and technical know-how. Our acupuncture needles are polished, respectively electro-polished and this way recieve their particularly smooth surface structure. - Finishing

The polished needles are coated with a filmy silicone layer on the whole length of the needle, that is also applied in the production of injection cannulas. The medical silicone of highest quality adheres strongly to the needle. Of course, every needle is sterilized and safely packaged. - Quality control

To ensure our product standard, the finished needles are subject to a strict quality control. Only acupuncture needles, that meet our high specifications will pass the quality check and be released into the market. By this means we make sure that both users and patients can rely on our products.